Your business needs to make uniforms but don't know how to optimize budget and costs? You wonder why uniforms have many different prices? Let's learn more about Sota Factors affecting uniform sewing prices Read the following article to gain more experience when ordering uniforms!

Index

Factors affecting uniform sewing prices

Uniform style

Design is one of the factors that affect the price of uniform sewing that we can see most clearly.

Uniforms with simple designs such as round neck t-shirts, plain shirts or basic skirts often cost less thanks to the quick sewing process and few processing steps.

On the contrary, uniforms with complex designs such as office suits, uniforms with many sophisticated cutting and sewing details, or requiring custom designs will have higher prices. The more sophisticated the design, the higher the technical requirements, the higher the price will be.

Therefore, before ordering, businesses or organizations should consider aesthetic factors and budget to choose the right style, avoiding unwanted costs.

Fabric material

Fabric material is one of the factors that directly determines the cost of a uniform. Each type of fabric has its own characteristics in terms of durability, elasticity, sweat absorption, breathability and feeling when worn, these factors directly affect the production cost. The higher the quality of the fabric, the more advantages such as high durability, good absorption and long-term shape retention, the higher the price.

For example, popular fabrics such as 65/35 cotton are often more affordable than high-quality poly pique, bamboo or kate silk. Meanwhile, high-quality fabrics such as bamboo, linen or kate silk are not only more expensive but also require more meticulous sewing techniques to maintain the right drape and shape.

Reference: Collection of high quality office uniform materials.

Number of uniforms

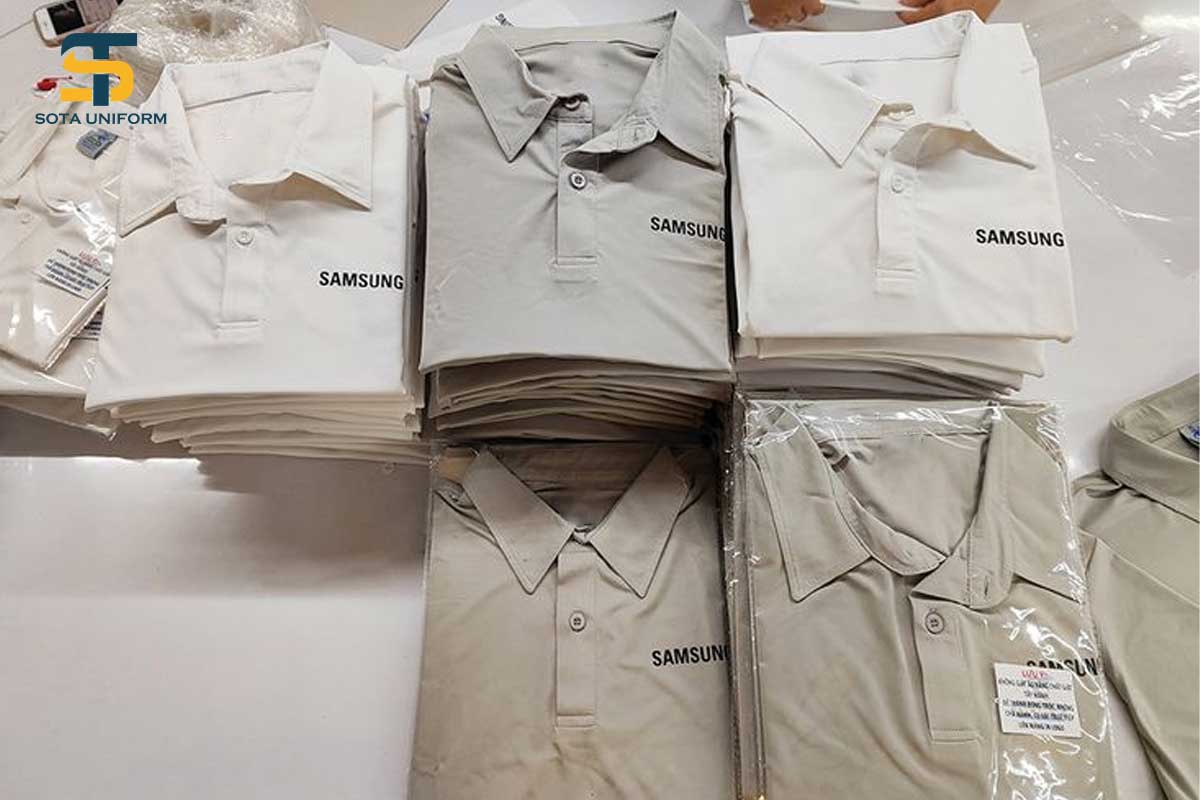

The next factor affecting uniform sewing price is the quantity of uniforms.

Normally, when ordering in larger quantities, the production cost per product will decrease thanks to saving on raw materials, labor and production time, thereby lowering the price.

On the contrary, if you only order a small quantity, the cost of cutting, sewing, operating machinery and materials will be spread over each product, leading to a higher price.

This is the reason why garment factories often have preferential prices or clear discounts for large orders. Therefore, when planning to order uniforms, determining the exact quantity from the beginning not only helps save costs but also helps suppliers easily advise the most optimal solution for you.

Reference: Note when ordering uniforms in bulk.

Embroidery printing technology

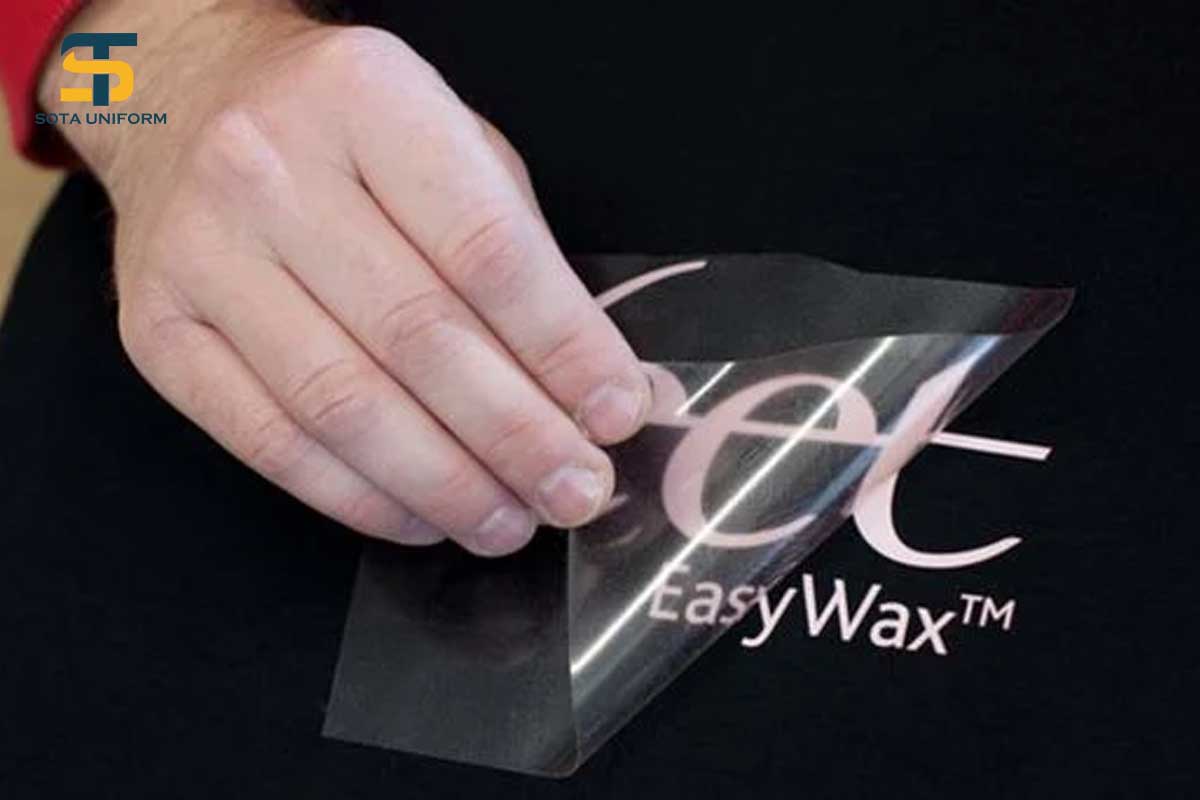

Each method such as screen printing, heat transfer printing, decal printing or computer embroidery has a different price, depending on the complexity, number of colors, print area and fabric material.

For example, screen printing is often more cost-effective when produced in large quantities, while computer embroidery feels premium and durable but costs more due to the meticulous and time-consuming process.

In addition, some designs require a combination of printing and embroidery techniques, which increases production costs. Choosing the right technology not only affects the budget, but also affects the durability, aesthetics and brand image when the uniform is actually used.

Reference: Popular logo printing techniques today.

Production time

One of the factors that affects the price of uniform sewing but few people think about is production time.

If you need your goods urgently, requiring them to be completed in a short time, this may entail overtime, rescheduling production or even mobilizing additional workers. All of these additional costs will be included in the unit price of the product.

On the contrary, if you plan to order early and are flexible about delivery time, the supplier will easily arrange production more optimally, thereby significantly reducing costs. Therefore, to save budget, proactively plan to order uniforms as soon as possible.

Uniform supplier address

Each garment unit will have different operating costs, production processes, service quality and pricing.

Large-scale garment factories with closed production systems often offer more competitive prices thanks to saving on intermediary costs. In contrast, retail stores or intermediaries often add a commission percentage, causing prices to increase significantly.

Therefore, choosing the right supplier not only helps you save costs but also ensures quality and delivery progress.

Reference: Experience in choosing a reputable uniform supplier.

The price of sewing uniforms is not only based on the design or material but also affected by many factors such as the order quantity, design level, printing/embroidery techniques, delivery time and especially the supplier address. Understanding these factors will help you be more proactive in choosing the right unit, balancing the budget and still ensuring the desired quality.

Contact Sota now for the most professional uniform accessory design and consultation!

- Fanpage: Sota Uniform

- Hotline: 0933 122 077