Printing logos not only increases brand recognition but also shows professionalism, sophistication and creates highlights for uniforms. However, to keep the logo sharp, durable and suitable for each fabric material, choosing the right uniform logo printing technique is the key factor. Join Sota to learn more about uniform logo printing technique through the following article!

Index

Why is it necessary to choose the right uniform logo printing technique?

Choosing the right logo printing technique plays an important role in expressing the professional image and brand value of the business.

Each printing technique has its own characteristics in terms of durability, color, detail and cost, so choosing the wrong method can lead to blurred, peeling, or unsharp logos, directly affecting the aesthetics of the uniform.

In particular, uniforms are often used for a long time and with high frequency, so applying the appropriate printing technique will help the logo maintain color fastness and clear image over time. In addition, choosing the right technique also helps save production costs, ensure progress and improve brand communication effectiveness.

Uniform logo printing techniques

Screen printing

Screen printing is an old logo printing technique but still the most popular today. In addition to manual screen printing, using a screen printing machine can print large quantities in a short time.

This method uses a silk screen to print ink onto the fabric surface, creating a logo image with bright colors, good ink adhesion and high durability. Silk screen printing is suitable for simple logo designs, few colors and does not require complex color transitions.

Similar to decal printing, silk screen printing is low cost and can be printed on many different fabrics, but the print life is not too long and can only print monochrome colors.

Heat transfer printing

Heat transfer printing includes 2 steps: printing on paper and pressing. The process is not complicated but still produces prints with beautiful colors, sharpness, and fast printing on many different materials. However, it can only be printed on light-colored shirts and colorfast fabrics.

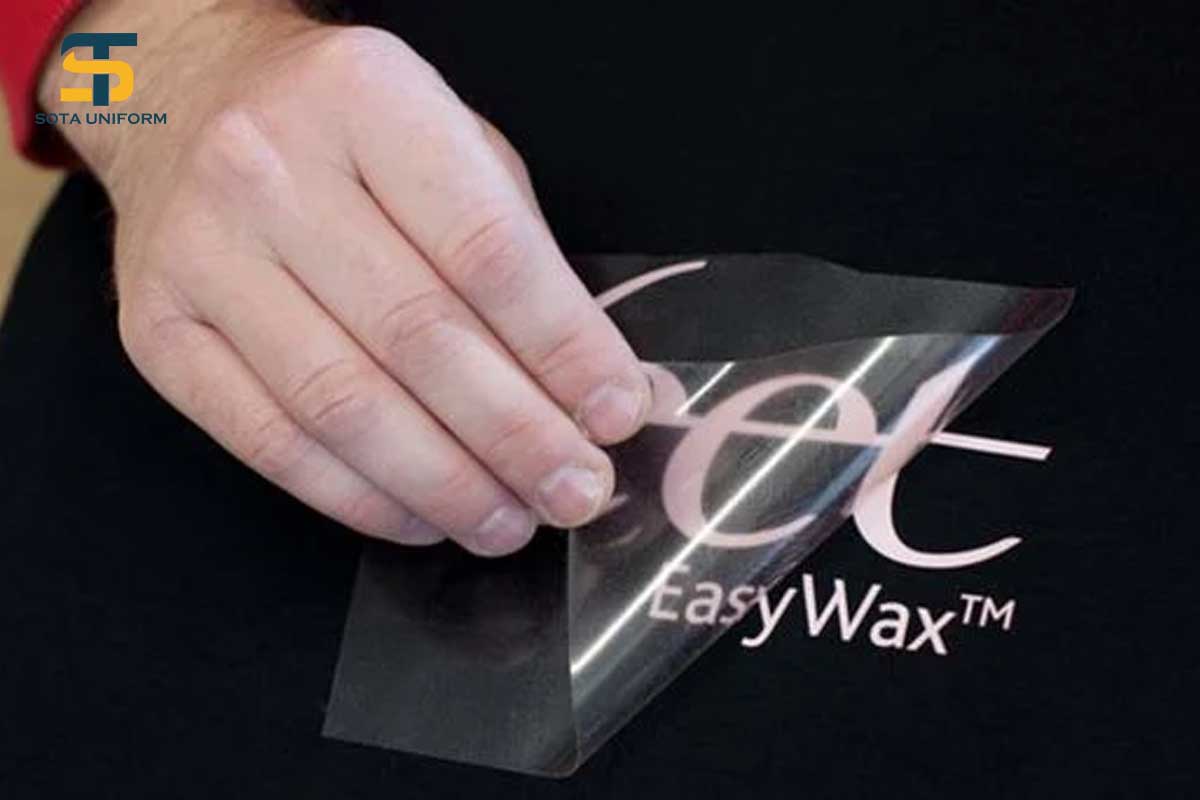

Decal printing

Decal printing is a type of label that has glue on the back and sticks to itself under pressure. With decal printing, on many different types of fabric, customers can still print any image they want. Decal printing is often used when printing small quantities, fast printing time, low cost but the usage time is not high.

Digital printing

Digital printing is done instantly, sprayed directly onto the fabric without any prepress. This method has a fast printing speed, is used for high resolution, sharp images and can be printed on many different materials. The printing process is done quickly and produces large quantities. However, the cost is quite high, requiring the use of specialized inks.

See also: Full uniform service: Advantages and benefits.

Choosing the right uniform logo printing technique not only helps to enhance the aesthetics but also contributes to affirming the brand image in a professional and sustainable way. Whether you prioritize durability, detail or cost, each printing method can meet the needs if applied correctly and for the right purpose. Carefully consider the fabric material, logo design and usage needs to make the most optimal choice.

Contact Sota now for more detailed advice on uniform logo design and printing!

- Fanpage: Sota Uniform

- Hotline: 0933 122 077